FSAE-EV Braking System

Role

Responsible engineer for Formula Electric at Berkeley's 2024-2025 braking system owning the design, analysis, manufacturing, and validation of all braking components except front and rear brake rotors. Took emergency ownership of chassis mounting rails to ensure structural integrity and meet key manufacturing deadline. Advised across all pedal box subsystems.

Timeline

July - Aug 2024 -> Reflection on prior car and research

Aug - Dec 2024 -> Analysis and design

Jan - Apr 2025 -> Manufacturing and assembly

Apr - May 2025 -> Rules check and debugging

May - June 2025 -> Testing

June 17 - 21 2025 -> FSAE-EV Competition

Benchmarking and Research

The project began with a deep dive into past failures and judge feedback. The previous car’s braking system suffered from improperly tuned brake bias, excessive assembly play and deflections, catastrophic pedal failure during competition, shaft binding issues, unsafe adjustment mechanisms, and serviceability nightmares.

Guided by team principles of safety, reliability, rule compliance, first-principles reasoning, and risk mitigation, I benchmarked both industry motorsport pedal boxes and past FSAE cars. This research revealed design paradigms and clarified the two most important success factors: ensuring the force required for wheel lock-up remained under 100 lbf (per Limpert’s Brake Design and Safety) and selecting hydraulic components that result in synchronous wheel lock-up during brake test.

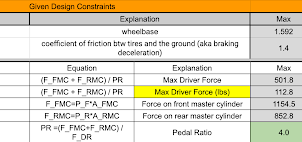

System Analysis

To set the foundation for the overall system design of the braking system, I developed a braking dynamics calculator in MATLAB that combined preliminary vehicle parameters, aero coefficients, and predicted tire-road friction coefficient to generate an ideal brake curve. This informed caliper and master cylinder selection which was validated through a hydraulics spreadsheet to confirm that pedal lever ratio, force-to-lockup, and theoretical bias bar setting were within acceptable ranges. Working with Brembo, we selected calipers and master cylinders that ensured sub-100 lbf pedal force and correct front and rear brake force distribution.

Architecture and Design Decisions

I started the design process by creating system diagrams that take inventory of what individual components comprise the braking system, their codependences, and affected sub teams.

After 2 rounds of preliminary design reviews, I locked-in several architectural choices that shaped the final system:

-

Adopted vertical master cylinders, reducing pedal box length, mass, and improving serviceability.

-

Removed unnecessary shaft encoder, simplifying the pedal shaft design and eliminating shaft binding.

-

Eliminated all friction fits and replacing them with clearance fits, easing manufacturing and assembly.

-

Designed for modular side-mount attachment of pedal, master cylinders, brake-over-travel switch, and fluid reservoirs, enabling top-down serviceability.

-

Conceptualized and later took emergency ownership of spring-pin-indexed dovetail rails, which replaced unsafe friction joints, made pedal box adjustment completely toolless, and increased assembly stiffness.

CAD and Analysis

Using a common origin assembly strategy in SolidWorks, I designed all custom braking components in context of a "sandbox" assembly to eliminate broken mates, ensure parametric consistency, and isolate changes from the top-level assembly. All key features such as hole positions, component widths, and equation driven geometry (e.g. pedal ratio) were referenced to a single master sketch. This allowed for quick iteration by forcing design changes to propagate to all components in the assembly. I applied FEA to the brake pedal and side mounts, but ultimately relied on first-principles hand calculations due to a lack of mechanical testing that proved that previous FEA setups were accurate.

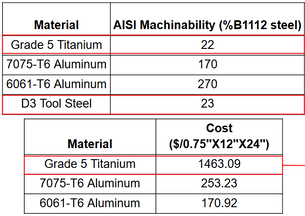

Manufacturing and Assembly

Once a thorough rules check was passed and the CAD was officially locked, I manufactured every custom component of the brake pedal assembly at the UC Berkeley student machine shop, using the manual lathe, manual mill, Omax waterjet, Fablight laser cutter, and general shop tools. I also supervised and tutored new members manufacturing pedal box and wheel assembly components. Finally, I supported brake system bring-up, debugging, and servicing education with pedal box assembly, brake line routing, and bleeding.

Outcomes

The redesigned braking system resolved all safety-critical flaws from prior cars, achieved an 8% reduction in pedal box mass, reduced the assembly and debugging stage by 2 months, and passed the brake test for the first time in team history at FSAE-EV Michigan after 3 years of failure. After minor bias tuning, all four wheels lock in unison, and even the smallest drivers can confidently generate the required pedal force as seen in the video above. This milestone allowed our team to compete in dynamic events for the first time, validating both the engineering process and the guiding principles that shaped my design.